grinding mills

Our horizontal and vertical stone grinding mills, along with our disc mill, deliver exceptional Danish quality and durability. With capacities ranging from 80 kg/hr to 2,000 kg/hr, these mills cater to various industries and applications.

The Diamant, Europemill Industrial, and Grindmaster stone mills help farmers, bakeries, cafes, and coffee shops produce organic, freshly stone-milled wholemeal flour, spices, and coffee. By preserving all essential nutrients, stone milling ensures healthier, more sustainable products. These mills maintain the natural flavor of the products without any fortification, offering a high-quality, authentic experience for those who prioritize both taste and nutrition.

Worldwide shipping

Danish design

More than 100 years of experience

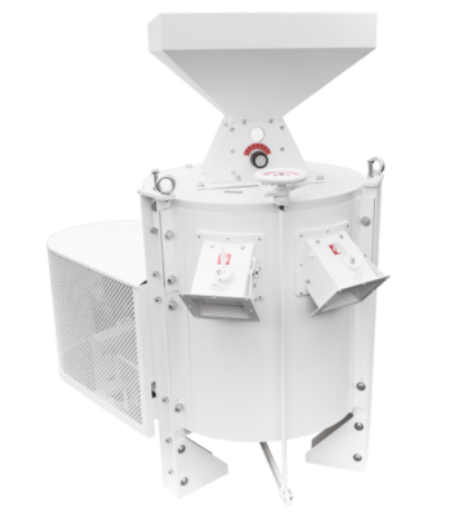

Discmill MHA 600

Grindmaster 950

Europemill Industrial

Europemill Standard

Combi Tabletop

Tabletop EM25/250

Diamant Vertical Mill

Handmill D.525

faq

Here are answers to some of the most frequently asked questions about stone milling

Can I buy spare parts for my stone grinding mill?

Yes, we have spare parts avaolable for our whole range of grinding mills, sifters and accessories

Do I need to learn any special skill to learn the craft of stone milling?

Stone Milling is a special craft so knowing how to mill with stone mills is a must. We offer training on site to all our customers

What does a stone grinding mill do?

A Stone Grinding Mill can grind different types of grains, spices, and coffee.

The product is ground between two millstones: a stationary stone and a runner stone.

Is stone milling products healthy?

Yes, not only is it healthy because it contains a natural balance of starch, protein, vitamins, and fibres, but it also preserves the essential vitamins B and E..

Which product can I grind?

You can grind all types of grains, different types of spices and coffee on ENGSKO grinding mills

Do you ship internationally?

Yes, to all countries by air, sea and land

Can you help with installation?

Yes, we have a full installation team that we will send out; both for installation, training and commissioning

How long time does the mill stone last?

The mill stone will last several years, depending on what you grind and how many hours per day you operate.

As an overall, our mill stone will last up to 3 years before you need to change it.

This is based on running the stones 8 hrs per day for 6 days per week.

How many times can the millstones be re-dressed?

The millstone can be re-dressed up to 3-4 times

How much space is required for a Grinding Mill Plant?

- Our Baker´s Choice Milling Plant requires 30-50 sqm for operation.

- Our Miller´s Choice 250 will require 75-100 sqm.

- Our Miller´s Choice 500 will require 100-150 sqm.

- Our Miller´s Miller´s Choice 1000 will require 150-200 sqm.