grinding mills

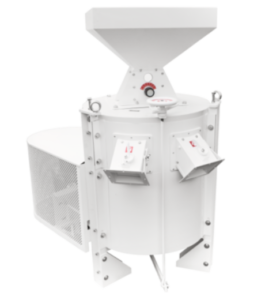

Grindmaster 950

In Engsko’s decentralized flour mills, the Grindmaster stone mill assumes a central role, providing a simple yet efficient method for milling high-quality flour. What distinguishes it is its dependence on a single milling break. This unique process involves combining stone milling without the need for additional refinement, resulting in a premium, finely ground flour. The straightforwardness of this approach, coupled with the utilization of the stone mill, guarantees a consistently superior flour output with

ease The Grindmaster stone mill professionally and simply does the Job through the optimum milling

process using proven and wellknown Engsko millstones in a sturdy design. The heavy duty mill,

aimed for industrial purposes, has a strong frame, hard-wearing shaft and bearings. The adjustment of

the stones has an adjustment gear for fine tuning. All in all an industrial mill used for grinding whole grain

into grits or healthy and good whole meal flour or for grinding of flour grits into high class flour as the last

break after a roller mill.

Technical data

- Motor power: 18,5 KW 400 V Electric, 50 Hz, European Standard, IE3

- Cap. Kg/h (fine/coarse): 250 - 800

- Dimensions: 1.880 x 1.050 x 1.632 mm

why grindmaster 950?

Meeting your needs for high-quality, healthy wholemeal flour, grits, or high-class flourExchangeable grinding elements in various corrugation patterns. Covers a wide range of applications

Highlight features

- The Grindmaster model is available in 3 versions for adjustment of the distance of the stones after start and befare stop of the stone mill.

- Completely dust free due to the construction of the machine

- The structure around the Grindmaster mill is made out of one bent round steel plate.

- Automatic presetting of millstones

grindmaster 950

In ENGSKO’s decentralized flour mills, the Grindmaster stone mill assumes a central role, providing a simple yet efficient method for milling high-quality flour. What distinguishes it is its dependence on a single milling break. This unique process involves combining stone milling without the need for additional refinement, resulting in a premium, finely ground flour. The straightforwardness of this approach, coupled with the utilization of the stone mill, guarantees a consistently superior flour output with

ease The Grindmaster stone mill professionally and simply does the Job through the optimum milling

process using proven and wellknown ENGSKO millstones in a sturdy design. The heavy duty mill,

aimed for industrial purposes, has a strong frame, hard-wearing shaft and bearings. The adjustment of

the stones has an adjustment gear for fine tuning. All in all an industrial mill used for grinding whole grain

into grits or healthy and good whole meal flour or for grinding of flour grits into high class flour as the last

break after a roller mill.

The Grindmaster stone grinding machine professionally and simply does the job through the optimum milling process using proven and wellknown ENGSKO millstones in a sturdy design.

The heavy duty mill aimed for industrial purposes, has a strong frame, hard-wearing shaft and bearings. The adjustment of the stones has an adjustment gear for fine tuning.

All in all an industrial mill used for grinding whole grain into grits/healthy and good whole meal flour or for grinding of flour grits into high class flour as the last break after a roller mill.

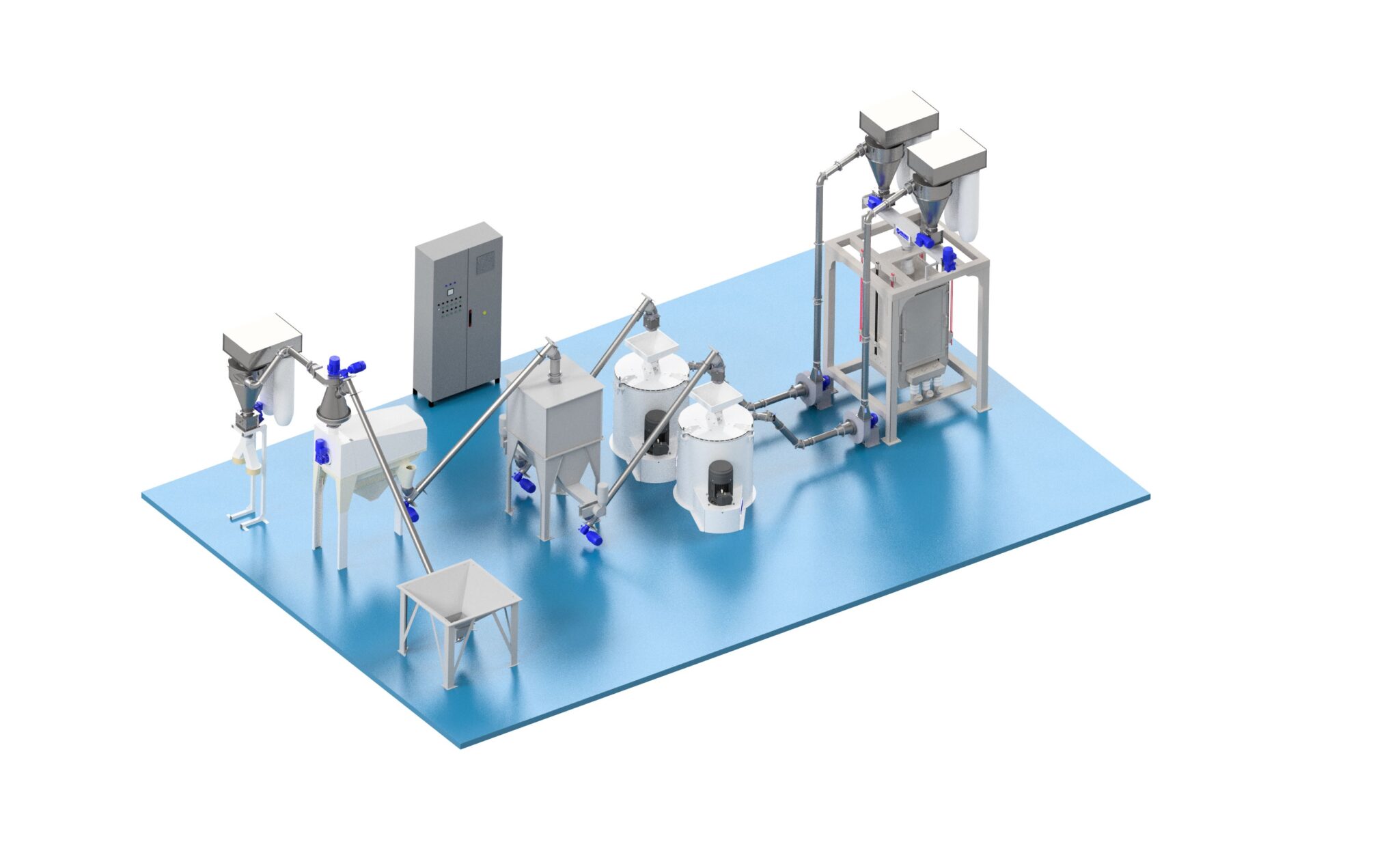

The superior thing about the Grindmaster stone mill when used in ENGSKO’s decentralized flour mills for milling high class flour at a high yield is that the process only uses 4 milling breaks.

In this unique combination of 3 break roller milling and 1 break stone milling the stone grinding machine produces a high quality, fine flour from the fine, white grits from the roller mill.

The flour produced on a Grindmaster stone mill machine contains all the natural vitamins and minerals in the grain and can be used for baking without further processing.

Furthermore, the stone ground flour has a large surface increasing the ability to absorb liquid, giving an airy and elastic dough easy to work with.

technical details

motor power

18,5 KW 400 V Electric, 50 Hz, European Standard, IE3

Cap. kg/h

Input capacity (fine/coarse) 250 - 800

dimensions

1.880 x 1.050 x 1.632 mm